pV Pre-Vault

| PROJECT DATA |

|---|

| TYPE | PAVILION FABRICATION |

|---|---|

| LOCATION | AARHUS, DENMARK |

| CLIENT | AARHUS SCHOOL OF ARCHITECTURE |

| DATE | 2011 |

| TEAM |

DAVE PIGRAM OLE EGHOLM-JACKSON NIELS MARTIN-LARSEN IAIN MAXWELL AARHUS SCHOOL OF ARCHITECTURE STUDENTS UNIVERSITY OF TECHNOLOGY SYDNEY EXCHANGE STUDENTS |

| AWARDS | BEST PAPER ENGINNERING OF COMPLEX GEOMETRIES ADVANCES IN ARCHITECTURAL GEOMETRY [AAG] CONFERENCE 2012 CENTRÉ POMPIDOU, FRANCE |

Pre-Vault

Aarhus, Denmark

pV

Algorithmic design and lasercut folded formwork enable the simple construction of a dynamic pavilion that uses far less material for itself, its formwork and its scaffolding.

The PreVault pavilion is a case study in the field of computational design and numerically controlled fabrication.

The structure implements a novel method for the construction of complex funicular structures from discrete precast concrete elements. It was produced for the 2011 Aarhus Architecture Festival in Denmark as a collaboration between researchers from the University of Technology, Sydney and the Aarhus School of Architecture.

This is the first structure of its type to fully integrate digital form finding techniques, computational file-to-fabrication workflows and innovative sustainable concrete casting techniques. Custom written dynamic relaxation software was used to define the overall form and successive algorithms then defined each component’s unique geometry, unrolled into flat shapes, and nested all parts into cut-files. PETG Plastic sheets were 2-Dimensionally laser cut and folded to produce the unique casting moulds. Fabrication and construction constraints were embedded within the design of both the overall structure and its components.

The constructed pavilion case study, constructed in a very short time, for low cost and with relatively unskilled labor demonstrates that the integration of algorithmic form-finding techniques, CNC fabrication workflows and the use of innovative PETG folded mould techniques enables the practical realisation of freeform funicular structures in pre-cast concrete. The pavilion and its innovative design and construction method is the focus of research papers presented at the 2012 ACADIA conference in San Francisco and the 2012 Advances in Architectural Geometry Conference at the Pompidou Centre in Paris.

Pavilion Plan

NTS

NTS

Footing Detail

The lowest precast concrete elements connect into a plywood floor which takes the tensile forces resulting from the vaults thrust.

The lowest precast concrete elements connect into a plywood floor which takes the tensile forces resulting from the vaults thrust.

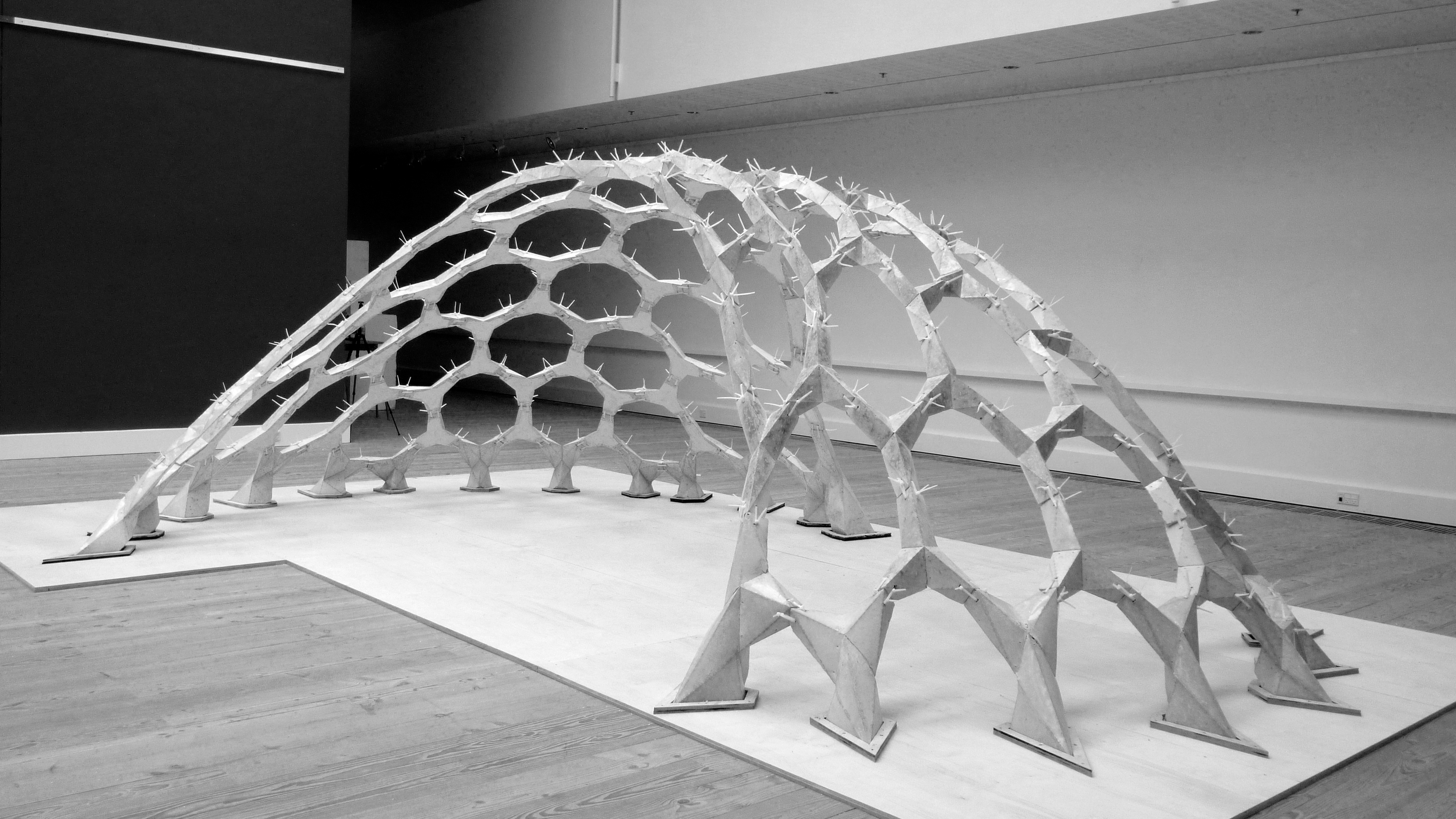

Structural Zipties

The pavilion is designed to take its self-weight in pure compression. Any additional live-load — the desigb load-case was two drunken Danes — would result in bending forces needing to be resisted by the joints.

Structural zip-ties, typically used for scaffolding, were an effective solution here seen untrimmed goving the pavilion a spikey charater before being trimmed.

The pavilion is designed to take its self-weight in pure compression. Any additional live-load — the desigb load-case was two drunken Danes — would result in bending forces needing to be resisted by the joints.

Structural zip-ties, typically used for scaffolding, were an effective solution here seen untrimmed goving the pavilion a spikey charater before being trimmed.

Lasercut PET Moulds

A key innovation underpinning the Pre-Vault pavilion is the use of lasercut 1mm thick aPET folded formwork.

This system requires far less labour, skill, time and material than conventional moulds and is 100% recycleable.

01

Initial mould design.

02

Refined mould design integrating reinforcement and joint connection elements.

A key innovation underpinning the Pre-Vault pavilion is the use of lasercut 1mm thick aPET folded formwork.

This system requires far less labour, skill, time and material than conventional moulds and is 100% recycleable.

01

Initial mould design.

02

Refined mould design integrating reinforcement and joint connection elements.

Aarhus Festival

The pavilion installed next to the cathedral in Aarhus for the Aarhus Festival 2011.

The pavilion installed next to the cathedral in Aarhus for the Aarhus Festival 2011.

Final Pavilion

The pavilion exhibited in the Aarhus School of Architecture Gallery.

The pavilion exhibited in the Aarhus School of Architecture Gallery.