iM Innovation in Masonry

| INNOVATION IN MASONRY |

|---|

| TYPE | APPLIED RESEARCH |

|---|---|

| PROJECTS |

SMART VAULT RE-VAULT RIBBED CATALAN |

| COLLABORATORS | WILLIAM SMART SMART DESIGN STUDIO - WES MCGEE MATTER DESIGN - PHILIPPE BLOCK BLOCK RESEARCH GROUP ETH ZURICH |

| PHOTOS | ROMELLO PEREIRA

DAVE PIGRAM MICHAEL FORD |

Caretakers Residence Interior

Designed by Smart Design Studio

[Main Image]

Designed by Smart Design Studio

[Main Image]

Innovation in Masonry

New Material Practices and Technologies

iM

For millennia, masonry construction techniques have been relied upon to create architectural space. The adoption of computational design and fabrication strategies offers a new lens through which to reimagine them.

Throughout history, masonry building techniques have underpinned society’s best endeavours to create dramatic and complex architectural spaces that negotiate the influences [and limitations] of physical forces, material properties and structural behaviours while navigating the complex issues, challenges and opportunities related to questions of labour and technique. In adopting digital — design and production — methods and workflows, our work explores the creative overlap of these spheres of influence, seeking out expressive new tectonic trajectories that both draw upon and exceed historical precedent.

Our work explores the role of the digital in addressing the many historical barriers associated with masonry construction: structural form, standardisation, stereotomy, tectonics, falsework and assembly.

Our work explores the role of the digital in addressing the many historical barriers associated with masonry construction: structural form, standardisation, stereotomy, tectonics, falsework and assembly.

Smart Vault — Computational Design

Supermanoeuvre director Dave PIgram worked as a geometry, computational-design and construction-innovation consulatant to William Smart and Smart Design Studio to assist in the design and realisation of the thinshell brick and shotcrete vaults that formed the caretaker’s residence above the Smart Design Studio’s new offices in Alexandria.

This process included writing custom code to place every brick digitally and to ensure a series of visual, technical and construction constraints could be respected simultaneously.

Supermanoeuvre director Dave PIgram worked as a geometry, computational-design and construction-innovation consulatant to William Smart and Smart Design Studio to assist in the design and realisation of the thinshell brick and shotcrete vaults that formed the caretaker’s residence above the Smart Design Studio’s new offices in Alexandria.

This process included writing custom code to place every brick digitally and to ensure a series of visual, technical and construction constraints could be respected simultaneously.

Smart Vault — 1:1 Prototype

A 1:1 prototype was constructed to test and verify the construction system, details and worflows. Samples harvested from the prototype were 3-point bending tested by the University of Technology Sydney’s TechLab to extract fundamental values used in engineering calculations.

The entire prototype was the destructively tested to verify adhesion between the brick and shotcrete layers.

Knowledge gained through the process of completing the 1:1 prototype provided enough confidence to reduce the thickness of the final construction yielding a reduction in embodied energy.

A 1:1 prototype was constructed to test and verify the construction system, details and worflows. Samples harvested from the prototype were 3-point bending tested by the University of Technology Sydney’s TechLab to extract fundamental values used in engineering calculations.

The entire prototype was the destructively tested to verify adhesion between the brick and shotcrete layers.

Knowledge gained through the process of completing the 1:1 prototype provided enough confidence to reduce the thickness of the final construction yielding a reduction in embodied energy.

Re-Vault — 1:1 Prototype

Hand-wound knitted vessel

Hand-wound knitted vessel

Re-Vault — Custom Formfinding Software

To support designing compression-only masonry structures that are aware of the constraints of production during early-stage design we have written a series of custom algorithms that can be interacted with in realtime through a purpose-made digital interface.

To support designing compression-only masonry structures that are aware of the constraints of production during early-stage design we have written a series of custom algorithms that can be interacted with in realtime through a purpose-made digital interface.

Re-Vault — Twisting Joints

The combination of hexagonal panelisation and twisting joints allows each voissoir to self-align and slightly cantiliver, supported by the previous row. This minimises the need for supporting falsework/scaffolding.

Re-Vault — Structural Analysis

01 [Left]

Equivalent [von-Mises] Stress

02 [Centre]

Total Deformation

03 [Right]

Vector Principal Stress

The combination of hexagonal panelisation and twisting joints allows each voissoir to self-align and slightly cantiliver, supported by the previous row. This minimises the need for supporting falsework/scaffolding.

Re-Vault — Structural Analysis

01 [Left]

Equivalent [von-Mises] Stress

02 [Centre]

Total Deformation

03 [Right]

Vector Principal Stress

Re-Vault — Robotic Waterjet Cutting

The swept joints of the sandstone slabs are enabled by the use of robotic waterjet cutting.

The swept joints of the sandstone slabs are enabled by the use of robotic waterjet cutting.

Ribbed Catalan

Traditional tile vaults are typically constructed springing off from walls or straight arches built from support element to support element on falsework. From these, the vault’s surface can be built in space with minimal or no guidework. Built on previous research and focusing on continuous surface expression and fully representing three-dimensional equilibrium surfaces in compression, this research explores the design potential of three-dimensional networks of structural ribs, made possible by new funicular form-finding approaches. This new structural typology for tile vaults was investigated and tested through an intensive, design-build workshops in Australia at the University of Technology Sydney (UTS) in co-taught by supermanoeuvre’s Dave Pigram with Philippe Block from ETH Zurich and Melonie Bayl-Smith from Bijl Architecture.

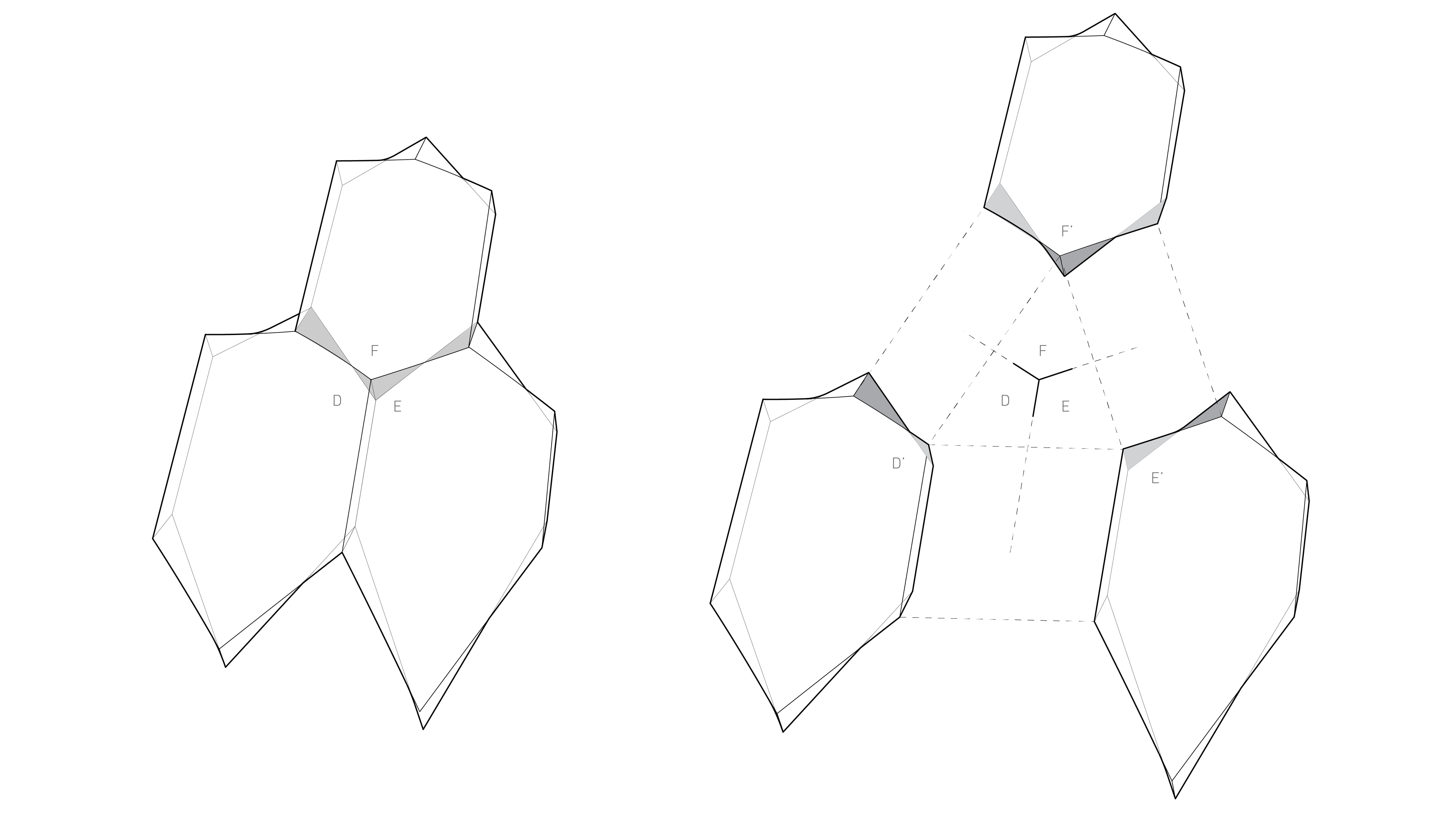

Exploded Axonometric

[Left]

01

Graphic Statics Force Diagram

02

Graphic Statics Form Diagram

03

Catalan Tile Vault Infill Panels

04

Primary Structural Ribs

05

Cardboard & Reused Foam Falsework

Final Pavilion

[Right]

Traditional tile vaults are typically constructed springing off from walls or straight arches built from support element to support element on falsework. From these, the vault’s surface can be built in space with minimal or no guidework. Built on previous research and focusing on continuous surface expression and fully representing three-dimensional equilibrium surfaces in compression, this research explores the design potential of three-dimensional networks of structural ribs, made possible by new funicular form-finding approaches. This new structural typology for tile vaults was investigated and tested through an intensive, design-build workshops in Australia at the University of Technology Sydney (UTS) in co-taught by supermanoeuvre’s Dave Pigram with Philippe Block from ETH Zurich and Melonie Bayl-Smith from Bijl Architecture.

Exploded Axonometric

[Left]

01

Graphic Statics Force Diagram

02

Graphic Statics Form Diagram

03

Catalan Tile Vault Infill Panels

04

Primary Structural Ribs

05

Cardboard & Reused Foam Falsework

Final Pavilion

[Right]