pT Periscope Tower

| PROJECT DATA |

|---|

| TYPE | ROBOTIC FABRICATION PAVILION INSTALLATION |

|---|---|

| LOCATION | ATLANTA GEORGIA, USA |

| CLIENT | YOUNG ARCHITECT’S FORUM ATLANTA |

| DATE | 2010 |

| TEAM | BRANDON CLIFFORD WES McGEE DAVE PIGRAM MATTHEW JOHNSON MACIEJ KACZYNSKI JOHANNA LOBDELL DENIZ McGEE KRIS WALTERS |

| PUBLICATIONS | FABRICATE 2011 MONITOR UNLIMITED #61, 2010 ARCHDAILY, 2010 |

| AWARDS | INTERNATIONAL WINNER MODERN ATLANTA 10UP! DESIGN COMPETITION |

Periscope Tower

Atlanta, Georgia, USA

pT

Custom file-to-factory algorithms directly generate robot instruction code to allow feedback between design, matter and making.

Periscope Tower is a robotically fabricated tower of foam. It was the winning entry in the 10Up! architecture competition in its inaugural year. Sponsored by the Young Architect Forum of Atlanta, the competition called for entries that could be constructed in twenty-four hours in a ten-foot by ten-foot plot. No height limit was given. Taking advantage of this oversight, the form of the tower inverts the structural rhetoric of what appears to be a tensile fabric lifted by impossibly thin compression rods. In reality, the sixty-foot tall tower is constructed of expanded polystyrene foam blocks that were robotically cut, stacked, and then placed in compression by tension cables that lash the very large and wind-prone installation to a heavy, stabilizing foundation.

The project was fabricated in the University of Michigan, Taubman College of Architecture and Urban Planning’s FabLab. The fabrication process utilized custom written software that directly generates robot instruction code eliminating the need for construction or shop drawings. This file-to-tactory workflow enabled an empirical feedback loop between formational processes and material properties.

The Periscope Tower demonstrates the design potential and real-world practicality and use value of the fabrication and algorithmic design techniques in terms of speed of assembly, weight, and relative affordability.

The project was fabricated in the University of Michigan, Taubman College of Architecture and Urban Planning’s FabLab. The fabrication process utilized custom written software that directly generates robot instruction code eliminating the need for construction or shop drawings. This file-to-tactory workflow enabled an empirical feedback loop between formational processes and material properties.

The Periscope Tower demonstrates the design potential and real-world practicality and use value of the fabrication and algorithmic design techniques in terms of speed of assembly, weight, and relative affordability.

Periscope and Reflected Views

Two embedded periscopes serve to position the viewer within the larger context of Atlanta.

Two embedded periscopes serve to position the viewer within the larger context of Atlanta.

Assembly Diagram

The tower consists of a stack of pre-fabricated foam

sub-assemblies sized for transport.

This stack is then post-tensioned via cables connecting to a water-filled ballast tank to ensure the stability of the ultra-light tower under windloads.

East Elevation

Shows periscope view cones capturing views to Atlanta’s downtown and midtown.

The tower consists of a stack of pre-fabricated foam

sub-assemblies sized for transport.

This stack is then post-tensioned via cables connecting to a water-filled ballast tank to ensure the stability of the ultra-light tower under windloads.

East Elevation

Shows periscope view cones capturing views to Atlanta’s downtown and midtown.

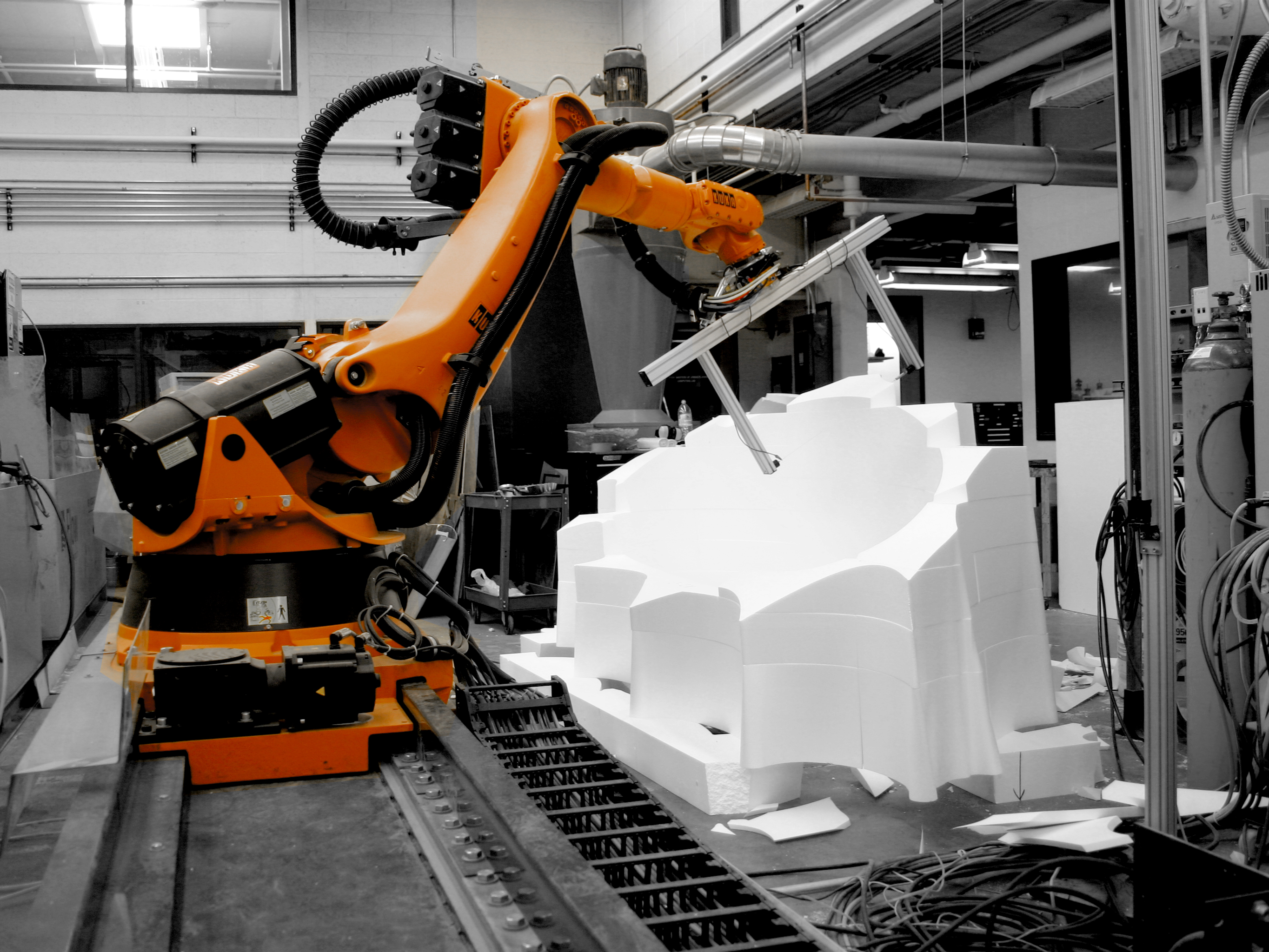

Robotic Hotwire Cutting

The University of Michigan’s Taubman College of Architecture and Urban Planning’s7-Axis Robotic Workcell was used in conjunction with ‘SuperMatterTools’ the custom-written robot control software.

The University of Michigan’s Taubman College of Architecture and Urban Planning’s7-Axis Robotic Workcell was used in conjunction with ‘SuperMatterTools’ the custom-written robot control software.

Fabrication Sequence

A photographic record of the many production steps required to produce this, the world's first robotically fabricated tower of foam.

A photographic record of the many production steps required to produce this, the world's first robotically fabricated tower of foam.

Completed Tower

The assembled tower is reminiscent of carved stone columns from a different millenium and shares the stereotomic assembly logic of its ancestors.

The assembled tower is reminiscent of carved stone columns from a different millenium and shares the stereotomic assembly logic of its ancestors.