sF Super Floater

| PROJECT DATA |

|---|

| TYPE |

ENERGY INFRASTRUCTURE STRUCTURAL INNOVATION CONSTRUCTION INNOVATION |

|---|---|

| LOCATION | DALLAS, TEXAS UNITED STATES OF AMERICA |

| CLIENT | TEXAS WIND TOWERS |

| DATE | 2021 — |

| TEAM | DAVE PIGRAM IAIN MAXWELL |

| COLLABORATORS | ALTAIR JORDAN POWELL |

| RENDERS | SUPERMANOEUVRE |

| AWARDS | BEST INTERNATIONAL ARCHITECTURE PRACTICE: DESIGN FOR DECARBONISATION BUILT DESIGN AWARDS [UK] |

Super Floater

Dallas, Texas, United Stated of America

sF

A patented disruptive design for offshore floating wind-turbine platforms with longer lifetimes, better environmental and economic performance and a lower Levelised Cost of Energy [LCOE].

Floating Offshore Wind Power is a key element of the shift to decarbonized energy production necessary to address the climate crisis. Key to achieving decarbonization of the energy sector is the cost-competitiveness of renewables measured via the Levelized Cost Of Energy [LCOE]. ‘Super Floater’ is both a design and a design process for Ultra-High Performance Concrete floating wind turbine platforms. ‘Super Floater’ lowers the LCOE of Floating Offshore Wind Power by enabling floating platforms that cost less to build and maintain; have longer service lives and reduce Capital Expenditure [CAPEX] and exposure to volatile steel markets. The approach may also open the possibility of larger floaters which have generally also resulted in lower LCOE. Additional societal benefits include local employment; reduced transport impacts and lower embodied and operational carbon.

The project’s innovation results from the combination of three main aspects:

01 - The use of Ultra-High Performance Concrete [UHPC] for Floating Offshore Wind Power in combination with 02 and 03 below.

02 - A multi-stage digitally-augmented design process that includes topological optimisation, structural and naval simulation, and fabrication-aware form-finding in tight feedback loops.

03 - A novel fabrication approach for complex doubly-curved branching nodes that in combination with conventionally constructed straight sections has the potential to unlock a commercially viable pathway to construct the forms developed by 02.

Texas Wind Towers, a startup-enterprise pioneering the development of floating wind tower technology, collaborated with supermanoeuvre and Altair, a software and consulting company, to develop an advanced workflow for the design, validation, and optimization of floating wind tower structures via computational design, topological and structural optimization technology and naval architecture software.

The project’s innovation results from the combination of three main aspects:

01 - The use of Ultra-High Performance Concrete [UHPC] for Floating Offshore Wind Power in combination with 02 and 03 below.

02 - A multi-stage digitally-augmented design process that includes topological optimisation, structural and naval simulation, and fabrication-aware form-finding in tight feedback loops.

03 - A novel fabrication approach for complex doubly-curved branching nodes that in combination with conventionally constructed straight sections has the potential to unlock a commercially viable pathway to construct the forms developed by 02.

Texas Wind Towers, a startup-enterprise pioneering the development of floating wind tower technology, collaborated with supermanoeuvre and Altair, a software and consulting company, to develop an advanced workflow for the design, validation, and optimization of floating wind tower structures via computational design, topological and structural optimization technology and naval architecture software.

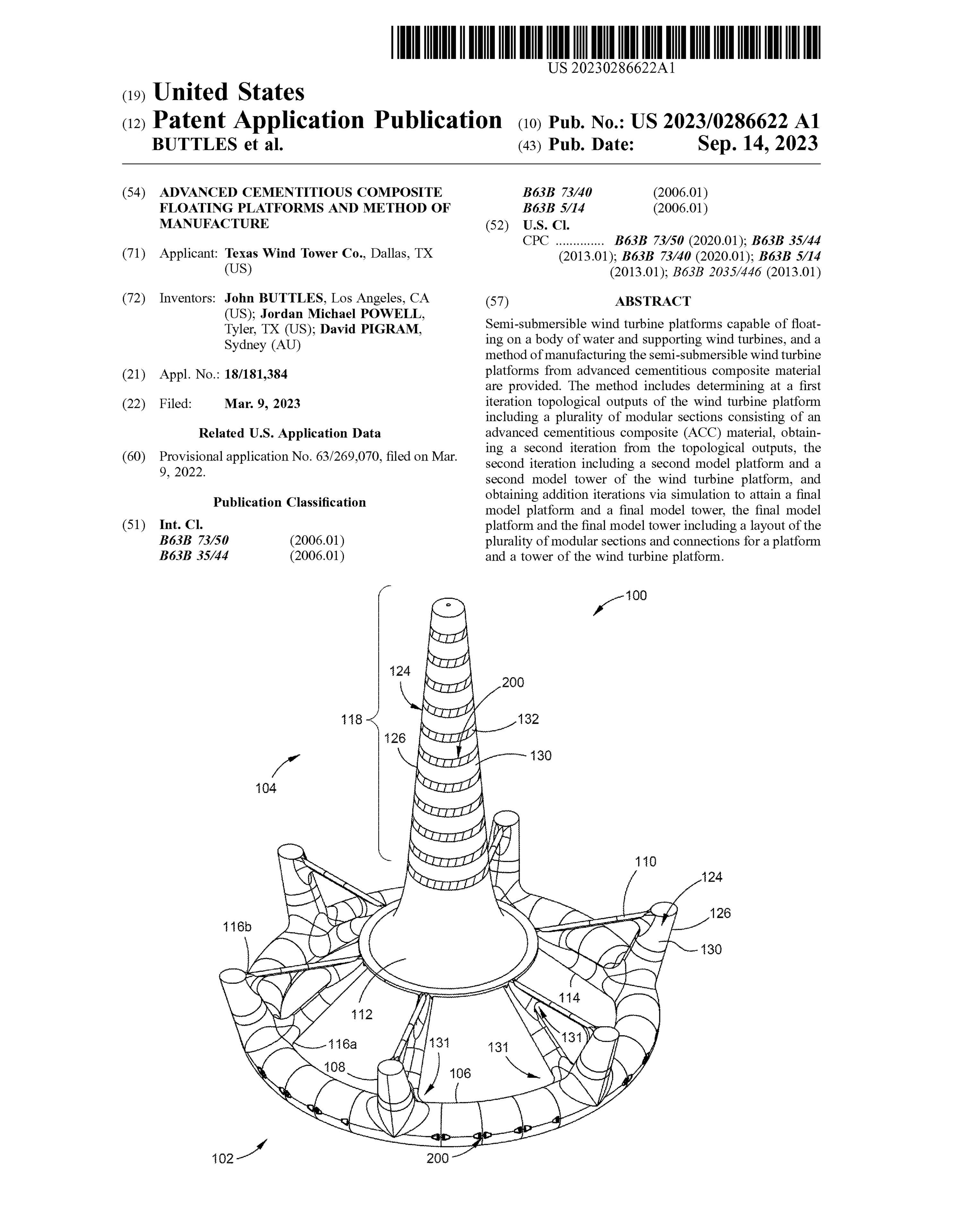

US Patent

Patent Number 11999451

Granted June 4, 2024

Patent Number 11999451

Granted June 4, 2024

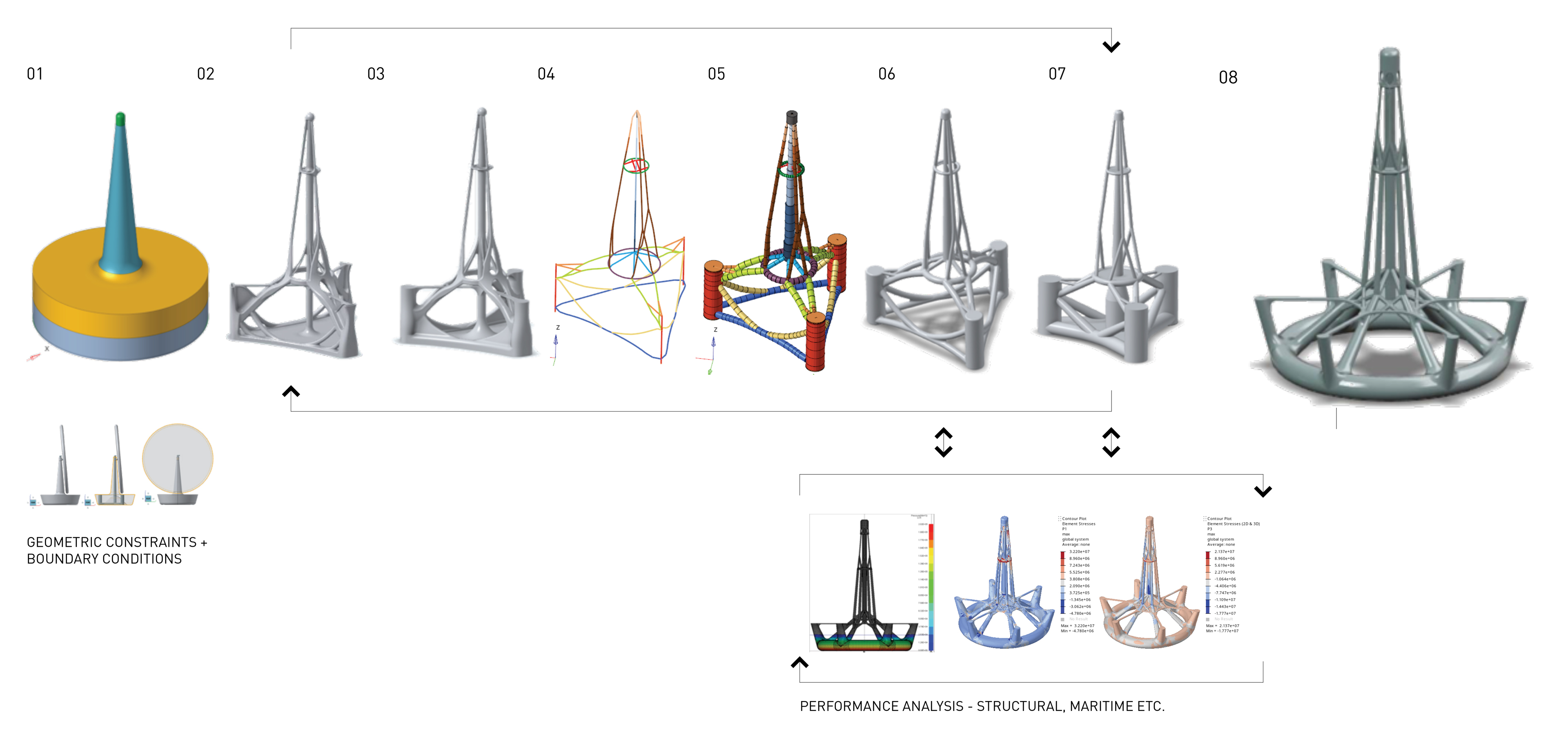

Multi-Stage Digitally-Augmented Design Process

The process of generating the form of the floating platform involves a number of steps and tight feedback loops combining structural and maritime performance simulations with fabrication-aware formfinding processes.

01

Input permitted design envelope, load cases, boundary conditions and non-design regions.

02

Structural topological optimization resolves constraints into a minimal material distribution; the process is enacted in Altair OptiStruct.

03

Add buoyancy components and adjust for stability.

04

Extra medial-axes as centerlines.

05

Interpret results from P3 into a manufacturable structure reflecting conditions of the proposed fabrication approach.

06

Determine Centre of Gravity [COG] and desired waterline. Use naval analysis MAESTRO to recheck COG and waterline – adjust size, thickness and ballast to achieve stability.

07

Extract hydrostatic loading from MAESTRO to isolate non-design within new boundary condition and repeat as P1.

08

Conclude with optimized FOWP design resulting from completed process.

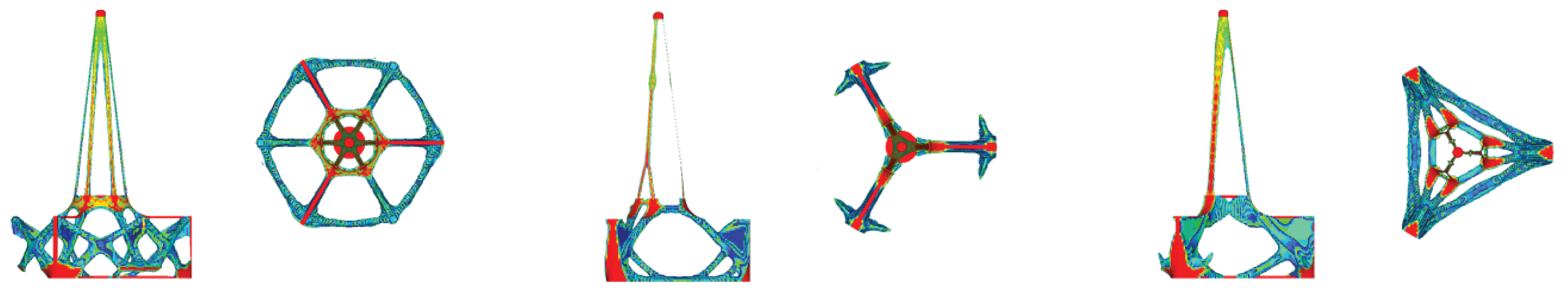

Topological Optimisation

Varying underlying platform typologies topologies emerge at different scales and with different boundary condition and load-case assumptions demonstrating the flexibility of the approach.

Varying underlying platform typologies topologies emerge at different scales and with different boundary condition and load-case assumptions demonstrating the flexibility of the approach.

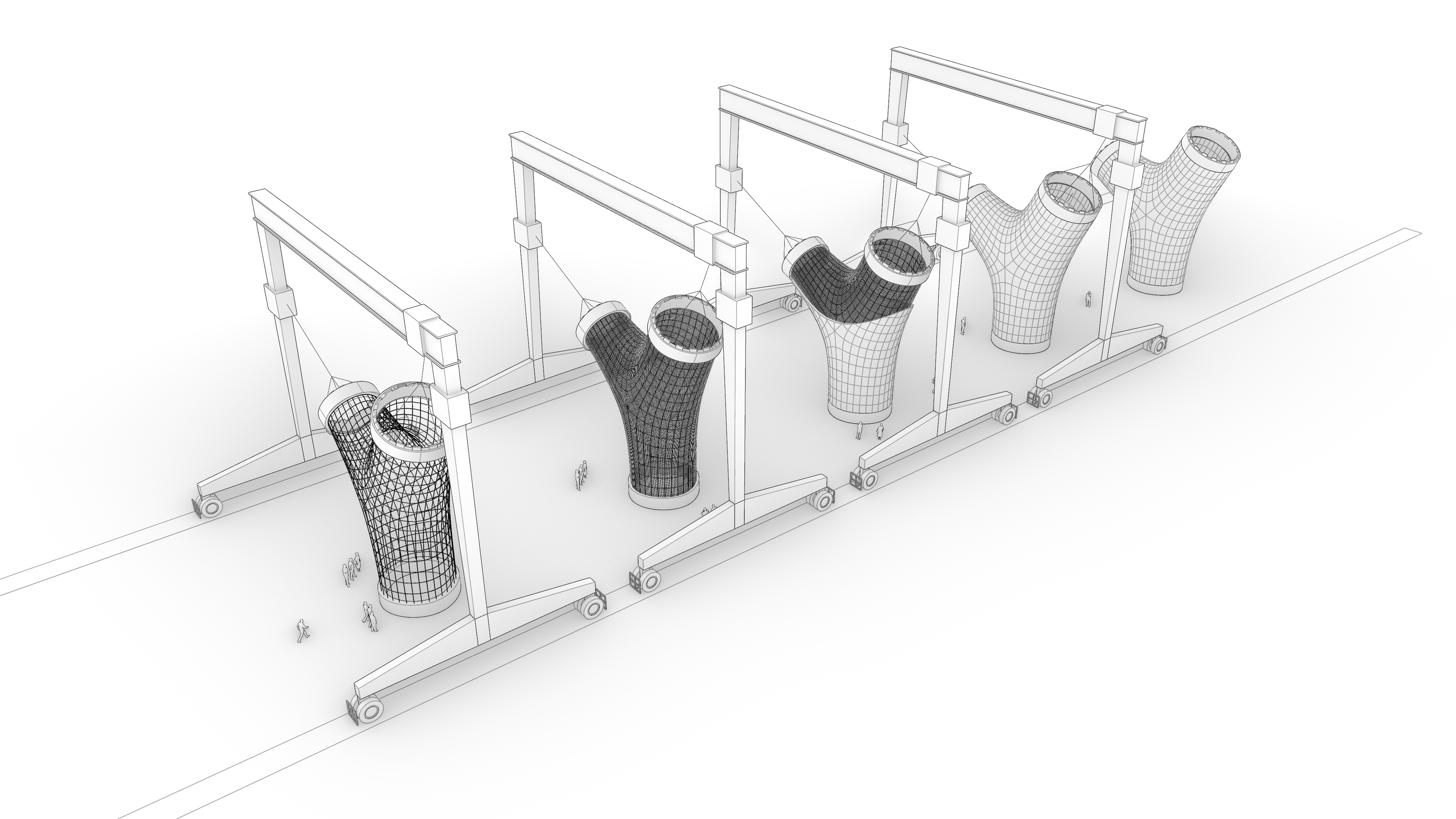

Dock-side Prefabrication

Large elements can be prefabricated adjacent to the launch site minimising transport costs and impacts.

Industrialised large node fabrication stages 05 - 09. The size shown represents the largest nodes at the bottom of a 160m tall Offshore Floating Wind Platform.

Large elements can be prefabricated adjacent to the launch site minimising transport costs and impacts.

Industrialised large node fabrication stages 05 - 09. The size shown represents the largest nodes at the bottom of a 160m tall Offshore Floating Wind Platform.

Platform Plan

The topologically-optimised 3-Dimensional space-frame consists of hollow custom Y-shaped nodes connected by hollow cylindrical members. Three-way rotational symmetry results from the minimum of three catenary tethers to the see floor below preserving location and stability.

The topologically-optimised 3-Dimensional space-frame consists of hollow custom Y-shaped nodes connected by hollow cylindrical members. Three-way rotational symmetry results from the minimum of three catenary tethers to the see floor below preserving location and stability.

Platform Elevations

The floats, structure and mast form a single integrated and highly efficient structure.

The floats, structure and mast form a single integrated and highly efficient structure.